In the world of home construction and energy efficiency, insulation is a pivotal component that can significantly influence energy consumption and comfort levels. As homeowners and builders pursue optimal solutions, two dominant players in the insulation arena often emerge: fiberglass and foam. Both materials are engineered to conserve energy by reducing heat flow, but they do so in distinct ways. This article delves into the intricate dynamics between fiberglass and foam insulation, exploring their respective advantages and disadvantages to guide informed decision-making for both residential and commercial applications.

The Insulation Battle: Fiberglass vs Foam

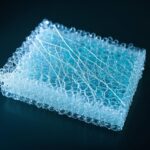

The insulation landscape is as diverse as the climates it serves, but fiberglass and foam have become the primary contenders due to their widespread use and relative affordability. Fiberglass insulation, characterized by its composition of fine glass fibers, is a traditional staple in the insulation market. It comes in batts, rolls, or loose-fill forms, offering flexibility for installation in various structural configurations. On the other hand, foam insulation, with its two main types—spray foam and rigid foam boards—represents a newer, technically sophisticated approach. Composed of polyurethane or polystyrene, foam insulation provides comprehensive coverage through expansive sealing capabilities.

Fiberglass has long been praised for its cost-effectiveness and ease of installation. It boasts a significant R-value, which measures thermal resistance, effectively retarding heat flow and enhancing energy efficiency. Its non-combustible nature provides an added layer of safety, making it a reliable choice for many construction projects. Foam insulation, however, is often touted for its superior sealing properties. Spray foam can expand to fill gaps, cracks, and voids, forming an airtight barrier that minimizes thermal bridging—a phenomenon where heat escapes through conductive materials.

Yet, each material is not without its set of drawbacks. Fiberglass can be prone to moisture absorption, which may lead to mold growth if not properly managed. Additionally, its installation process can be a skin irritant and requires protective gear. Foam insulation, while offering outstanding insulation properties, can be more expensive upfront and demands precision in application to prevent off-gassing or structural issues. Understanding these inherent characteristics is crucial for determining which insulation type best suits specific project needs and environmental conditions.

Comparing Efficiency and Benefits in Detail

When it comes to efficiency, both fiberglass and foam exhibit unique strengths that cater to different insulation demands. Fiberglass, with its layered composition, provides consistent thermal resistance and soundproofing capabilities, making it a popular choice for interior walls and attics. Its performance, however, is contingent upon proper installation and maintenance, as any compression or moisture infiltration can degrade its insulating properties. In contrast, foam insulation is renowned for its ability to create a continuous thermal envelope. Spray foam, in particular, excels at air sealing, which can significantly reduce energy loss and utility bills over time.

Beyond thermal efficiency, other factors such as environmental impact and sustainability also play crucial roles in evaluating insulation options. Fiberglass insulation is often heralded for its recyclability, as it can be made from recycled glass, contributing to reduced landfill waste. This eco-friendly aspect, combined with its cost-efficiency, makes fiberglass an attractive choice for environmentally conscious builders. Foam insulation, however, is gradually evolving to meet green building requirements, with newer formulations designed to reduce ozone depletion and improve indoor air quality.

The benefits of each insulation type extend beyond mere efficiency metrics. Fiberglass is relatively simpler to install in retrofitting scenarios, allowing for quick upgrades without extensive structural modifications. Foam insulation, with its high R-value per inch, is ideal for maximizing insulation in confined spaces where thickness constraints are a concern. Ultimately, the decision between fiberglass and foam often hinges on specific project priorities, budget considerations, and the desired balance between initial investment and long-term energy savings.

Choosing between fiberglass and foam insulation is more than just a matter of preference; it’s a strategic decision that affects the sustainability, comfort, and economic efficiency of a building. As we weigh the benefits and limitations of each material, it becomes clear that both have unique qualities suited to different applications. While fiberglass offers affordability and ease of use, foam provides unmatched sealing capabilities and efficiency. The ideal choice will depend on individual project requirements, environmental considerations, and financial implications. As technology advances and new formulations emerge, homeowners and builders will continue to benefit from improved insulation solutions that meet the demands of modern living.